Some Known Questions About Inventory Management.

Wiki Article

The Best Guide To Inventory Management

Table of ContentsThe Best Guide To Inventory ManagementThings about Inventory ManagementSome Ideas on Inventory Management You Should KnowInventory Management - An OverviewInventory Management for Dummies

The routine supply system is a method of stock valuation for monetary coverage objectives in which a physical count of the stock is carried out at certain intervals. This accounting technique takes stock at the beginning of a period, adds new supply purchases throughout the period as well as subtracts finishing stock to obtain the expense of items offered (COGS).They can link a number of information indicate the number, including the vendor, product dimensions, weight, as well as even variable information, such as the number of remain in supply. RFID or superhigh frequency recognition is a system that wirelessly transmits the identification of an item in the form of an one-of-a-kind serial number to track things and offer thorough product details.

All about Inventory Management

Inventory monitoring refers to the process of storing, purchasing, and marketing of items and also services. One of the most important aspects of supply monitoring is managing the flow of raw materials from their purchase to complete products.An oil depot can keep a big stock for a lengthy time. Or for businesses that deal in subject to spoiling products, such as fast-fashion products, keeping on top of your stock can be really pricey. One means to represent supply is by grouping it into 4 groups: first-in-first-out, last-in-first-out, weighted-average, and also first-in-first-out.

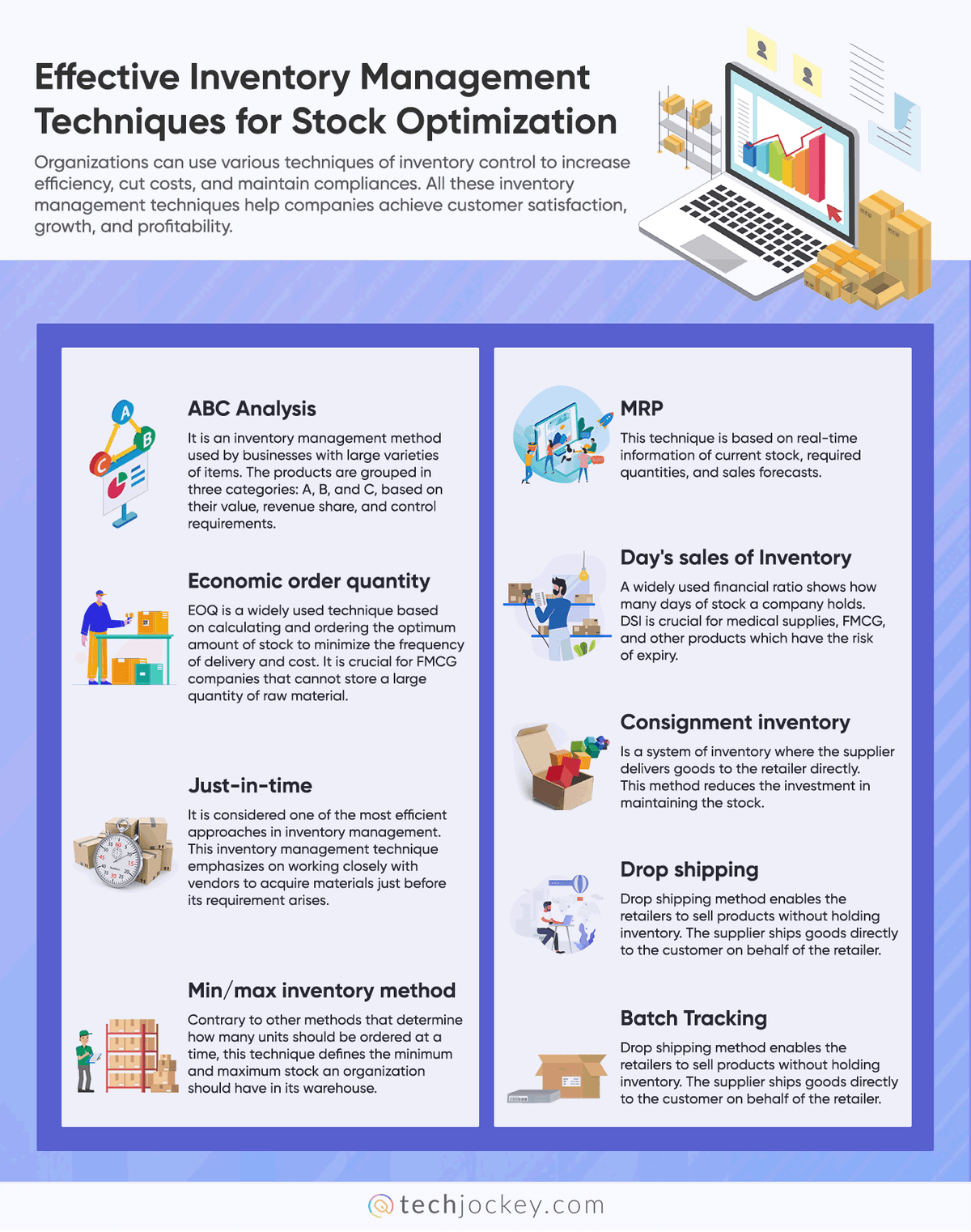

Depending upon the sort of company that it is dealing with, various inventory administration techniques are used. A few of these include JIT, product demand preparation, and days sales of inventory. Various other methods of examining stock can additionally be made use of relying on national and also neighborhood guidelines. For instance, the SEC calls for public business to report the existence of a supposed LIFO book.

The 9-Minute Rule for Inventory Management

Discover a lot more regarding stock management from Walton College's Supply Chain Administration program's introduction on the subject covering whatever from projecting to direct designs: One of the most important possessions of a company is its supply. Inventory Management. In various industries, such as retail, food solutions, and production, a lack of stock can have damaging results.It can be vulnerable to burglary, damage, as well as putridity. Having a large stock can also lead to a decrease in sales. Both for local business as well as huge firms, having an appropriate inventory administration system is really essential for any company. It can aid you track all your supplies and also identify the exact rates.

Balancing the dangers of overstocks and lacks is a particularly tough procedure for firms with complex supply chains. A Find Out More firm's supply is generally a present asset that it plans to offer within a year.

Inventory Management for Dummies

This means permitting them complete openness right into their chain to keep track of the circulation of goods from their vendor. The advantages are both operational as well as economic. Not only will it offer to enhance efficiency, however it's additionally useful for stopping theft with the aid of item monitoring as well as safety. Supervisors can likewise aim to utilize their inventory monitoring plan to keep track of sales procedures which results in much better service.

Giving customers numerous different kinds of internationally-grown fruit and vegetables in both natural as well as non-organic varieties at a budget friendly rate, even when the vegetables and fruits aren't in period, is i was reading this a modern wonder many thanks partially to stock administration. Supervising stock in actual time and also setting up automated replenishment systems is mission-critical to lots of.

Not known Details About Inventory Management

Their Smart Storage facility makes use of robot and also human assistance to obtain the work done, but it's stock management that keeps it all rolling. The inventory monitoring of toilet paper business was in the hot seat in very early 2020 as panic-buying led to shortages across the country.

Right here are the main types you should understand: Raw materials, This describes pieces of your product that need to be shipped to you and assembled by your team. Supply systems that track these should account for distributor timelines. Underway, Products made from raw products as well as are presently being set up or organized autumn under this classification.

Report this wiki page